- Home

- REBAR

Rebar made easy. Everytime

End-to-end solutions you can trust for post-installed rebar applications

Post-installed rebar can be used to build most connections on site – for instance, walls, slabs, beams, foundations or supporting columns. The full process can be tedious and time consuming but you can overcome these challenges with our end-to-end solutions for a safer and more reliable installation. Our solution starts from design to meet local regulations, selecting the right products and installation with the latest technology. Read on to find out how you can increase performance and productivity with Hilti.

COMPLIANT DESIGN

Post-installed rebars are used to connect two concrete members and is an essential application in building construction and infrastructure projects. Rebars become part of the structural system and must be designed as carefully as the entire structure. While European Technical Approvals prove that in basic load situations, post-installed rebars behave like cast-in bars, number of differences needs to be considered in special design situations such as fire or load cases where hooks or bends would be required for cast-in anchorages. The task of structural rebars is to take tensile loads and since concrete failure is always brittle, reinforced concrete design assumes that concrete has no tensile strength. Therefore despite the application, all rebar applications must be designed.

Importance of Design

COMPLIANCE

Local rules, codes and safety regulations – your correct and compliant specification is a top priority. Our ready-to-implement specification note can be plugged into your rebar specification to help ensure code compliance and help guide your jobsites' installations.

OPTIMIZATION

Let's face it, Eurocode does not cover all 'jobsite realities'. So we've developed the HIT Rebar method, and designed several solutions for post-installation rebar builds, which include concepts to overcome the limitations of structural concrete codes.

SAFETY

Different elements have a direct impact on the quality of the installation. Such as, but not limited to cleaning, minimum concrete cover, scanning for existing bars, roughening of concrete, injection accessories and drilling aids.

APPROVED PRODUCTS

-

Ultimate

- Ultimate performance for demanding applications

- Highest overall productivity and safety benefits

- Highest reliability in toughest conditions such as fire, seismic, corrosion, & more

- Complemented by world-class engineering and software support

- Most optimised designs

Premium

- Premium performance for wide range of applications

- High productivity through Hilti system solutions

- Impressive versatility and reliability

- Cost effective solution

- Standard approvals for use in cracked & uncracked concrete

Standard

- Hilti quality at economical price

- Standard solution for non-engineered applications

- Technical data support such as recommended load and installation requirements

PROPER INSTALLATION

Which Cleaning Method Do You Use?

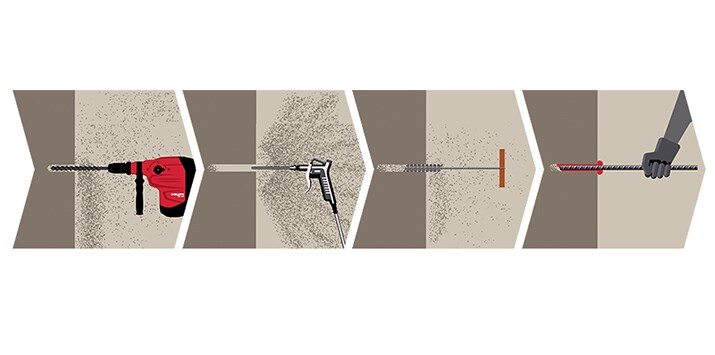

TRADITIONAL METHOD

What is the "Blow twice, brush twice, blow twice" method?

This traditional method can be used with epoxy and hybrid chemical anchors.

However, the process can be time consuming and leave more room for error.

What do you need?

- Wire Brush

- Air Compressor / Blow-out Pump

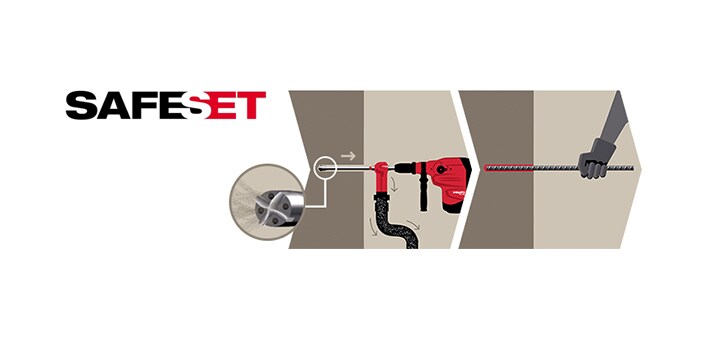

Safeset method

What is the Hilti SafeSet cleaning method?

SafeSet is a proven system that automatically cleans the hole as you drill. This more efficient process requires a Hilti hollow drill bit and an appropriately sized Hilti vacuum cleaner.

When used correctly, SafeSet can save you up to 45% of the installation time.

What do you need?